Sand blasting experience

Sand blasting experience

guys,

have you done your own sand blasting?

It's going to be a long time before I start body/paint work but like to hear about your experiences.

how much could someone expect to pay to have someone sand blast entire body/truck/frame, etc...??

how much do you think it would cost in materials alone?

pretty easy to do?

thanks,

have you done your own sand blasting?

It's going to be a long time before I start body/paint work but like to hear about your experiences.

how much could someone expect to pay to have someone sand blast entire body/truck/frame, etc...??

how much do you think it would cost in materials alone?

pretty easy to do?

thanks,

-

712edf

- Sweptline.ORG Pioneer

- Posts: 4037

- Joined: Fri Feb 15, 2008 8:46 pm

- City: Wichita Falls

- State: TX

- Location: wichita falls,texas

Re: Sand blasting experience

Requires big air compressor to do it properly w/o overworking it.

There are various media (sand, walnut shells, soda) for use with differing metals. Thick metal, such as frames, doesn't behave the same as body panels. More than one hood has been warped/ruined by someone who didn't know what they were doing.

I haven't done it myself, but paid someone to do some parts, such as bellhousing. If you take it to someone & are willing to wait for them to do your parts at the same time as they are doing other customer's stuff, you may get a price break. I have gotten stuff blasted for free just because I left it & they threw it in with a larger order, but I knew the guy.

Bucky

There are various media (sand, walnut shells, soda) for use with differing metals. Thick metal, such as frames, doesn't behave the same as body panels. More than one hood has been warped/ruined by someone who didn't know what they were doing.

I haven't done it myself, but paid someone to do some parts, such as bellhousing. If you take it to someone & are willing to wait for them to do your parts at the same time as they are doing other customer's stuff, you may get a price break. I have gotten stuff blasted for free just because I left it & they threw it in with a larger order, but I knew the guy.

Bucky

- 68dually

- Sweptline.ORG Member

- Posts: 227

- Joined: Sat Mar 12, 2011 8:07 pm

- City: turbotville

- State: PA

Re: Sand blasting experience

You can do it your self but it is time consuming. Professionals are set up so it goes faster and they can recycle their material. If you do it yourself , make sure you sand large flat areas (like the roof and hood) to remove as much of the paint as possible. This will prevent you from having to sandblast for long periods on metal that can be warped easy , plus it's much faster. Sandblasting is the only way to go for sharp body lines and hard to get areas like inside fenders.  Randy

Randy

Re: Sand blasting experience

thanks,

if I had it sandblasted by a professional, would you still recommend stripping the paint first?

if I had it sandblasted by a professional, would you still recommend stripping the paint first?

- dodgeboykim

- Sweptline.ORG Pioneer

- Posts: 3016

- Joined: Wed Dec 31, 1969 6:00 pm

- City: Chilliwack. B.C. Canada

- State: Foreign

- Location: chilliwack.

Re: Sand blasting experience

dlynes wrote:if I had it sandblasted by a professional, would you still recommend stripping the paint first?

Then why bother sandblasting it then. The point of sandblasting is to totally remove the paint and will also remove weak rusty metal.

Re: Sand blasting experience

712edf is right . I have a 80 gallon 5hp REN14 Champion compressor rated at 19 scfm and it works well with my Truman 99 sandblaster, but this is a "small" sandblaster and it still works out my compressor. Tip size ID is a determining factor on how huge you need to go on the compressor. A 3/32 tip uses 10 cfm of air with 100 lbs of sand per hour and will blast 1/2 to 1 square feet per minute. Go up just a little to 5/32 and now you need a compressor capable of 25 cfm @ 200 lbs of media per hour with 2-2 1/2 square feet per min. Blasting is not for the meek as it is messy, time consuming and above all requires all the right type of equipment and safety gear; i.e. respirator, hood, gloves, long sleeve jacket, etc. Respirator is Priority one. Then comes technique and how clean you want your metal . My experience has been to spend good money on your air system and filtration of the air. Avoid the " Harbor Freight Syndrome" of cheapness. Oh -One other thing is parts in a sandblasting system wear out and need to be replaced at regular intervals like tips, hose, fittings , etc.

- 68dually

- Sweptline.ORG Member

- Posts: 227

- Joined: Sat Mar 12, 2011 8:07 pm

- City: turbotville

- State: PA

Re: Sand blasting experience

A good body man will remove most of the paint on large flat areas first because of the possibility of warping and then blast that area as well. That way the blasting will only take a fraction of the time. Once you talk to him and find out what he recommends , you can do the sanding yourself and save yourself $50 an hour  . Make sure you try to keep away from sanding sharp body lines because you can easy put flat spots on them and they'll stick out through your new paint job like a sore thumb if they're not fixed. As far as price goes it will be expensive if you hire it all done. Most places charge $40 or $50 an hour for any labor , plus materials. When I had my fenders blasted it took a few hours to do them both inside and out.

. Make sure you try to keep away from sanding sharp body lines because you can easy put flat spots on them and they'll stick out through your new paint job like a sore thumb if they're not fixed. As far as price goes it will be expensive if you hire it all done. Most places charge $40 or $50 an hour for any labor , plus materials. When I had my fenders blasted it took a few hours to do them both inside and out.

Hope this helps , Randy

Hope this helps , Randy

- CSS-Registry

- Administrator

- Posts: 3715

- Joined: Wed Dec 31, 1969 6:00 pm

- City: Gainesville, Florida

- State: FL

- Location: Gainesville, Florida

- Contact:

Re: Sand blasting experience

i had my fully disassembled truck media blasted using recycled plastic. the pro charged me $1800 for everything - hood, fenders, cab, bed, doors - inside and out. i started sanding it myself to save money. it was so much faster to have a pro do the dirty work and allowed me to focus on things i was better at. i did the frame myself though...

here's a recent pic of the truck:

Ben

here's a recent pic of the truck:

Ben

- CSS-Registry

- Administrator

- Posts: 3715

- Joined: Wed Dec 31, 1969 6:00 pm

- City: Gainesville, Florida

- State: FL

- Location: Gainesville, Florida

- Contact:

Re: Sand blasting experience

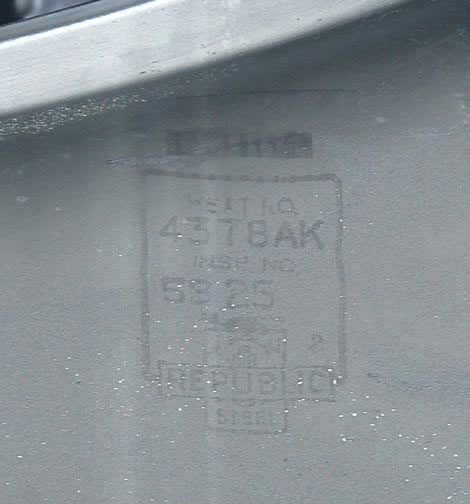

here's another photo that reveals how gentle media blasting is on sheet steel:

this was the stamp the steel manufacturer put on the fender BEFORE it was a fender. sand as a medium would have stripped this off and thinned the metal. plastic media simply took the paint off.

Ben

this was the stamp the steel manufacturer put on the fender BEFORE it was a fender. sand as a medium would have stripped this off and thinned the metal. plastic media simply took the paint off.

Ben

- soopernaut

- Sweptline.ORG Pioneer

- Posts: 8931

- Joined: Wed Dec 31, 1969 6:00 pm

- Location: Des Moines,IA

Re: Sand blasting experience

I don't have much sandblasting experience but I did blast some bumper brackets. I used a friend's setup. It takes quite a bit of time and I'd imagine you'd need a huge setup to do body panels and frames.

I think Nfury8 sandblasted his truck body. Look in his build thread.

Did you look into chemical dipping?

I think Nfury8 sandblasted his truck body. Look in his build thread.

Did you look into chemical dipping?

-

nytemuvr

- Sweptline.ORG Pioneer

- Posts: 915

- Joined: Tue Apr 10, 2012 9:49 pm

- City: Rio Linda

- State: CA

Re: Sand blasting experience

Walnut shelled my whole Challenger outside sheet metal in '97 for $400....sure it's a lot more now. Looked pretty cool without paint, just raw.

Re: Sand blasting experience

Man I love that Republic Steel heat stamp !! That is something that is rarely( never) if ever seen on metal . A testament to media blasting with plastic. If it were a plane , you could trace it all the way back to the manufacturer with a stamp like that. COOL post --

- facechicken

- Sweptline.ORG Pioneer

- Posts: 2215

- Joined: Fri Nov 05, 2010 10:32 am

- City: Baileyville

- State: KS

- Location: NE Kansas

- Contact:

Re: Sand blasting experience

I have sand blasted and here's what I found, use LOW pressure (can't remember what I set mine to but it was in the low double digits). It also helps to use extremely fine sand, almost powder like sand. Using both of those and a good steady swipping back and forth slowly (constant movement, don't stop on one spot to get it all off at once) and its not that bad. Definately need breathing apperatus, a good full head hood with a plexiglass space to look out of, safety gogles to were under your hood(can never be to careful with thousands of tiny rocks flying everwhere), long sleeve jacket (doesn't matter what material you use, if you don't use leather welding sleeves then the sand is gonna richocet and hit your skin through whatever your wearing anyways) good leather gloves (again think welders gloves). With all that and some patience you should do fine

- reallylongnickname

- Sweptline.ORG Member

- Posts: 525

- Joined: Wed Dec 31, 1969 6:00 pm

- City: Ottawa, Ontario

- State: Foreign

- Location: Ottawa, Ontario

Re: Sand blasting experience

Hello, I see this is a very old thread, but I’d to ask if plastic media will remove rust, or is a harder media needed?

- reallylongnickname

- Sweptline.ORG Member

- Posts: 525

- Joined: Wed Dec 31, 1969 6:00 pm

- City: Ottawa, Ontario

- State: Foreign

- Location: Ottawa, Ontario

Re: Sand blasting experience

Hello, I see this is a very old thread, but I’d to ask if plastic media will remove rust, or is a harder media needed?

- CSS-Registry

- Administrator

- Posts: 3715

- Joined: Wed Dec 31, 1969 6:00 pm

- City: Gainesville, Florida

- State: FL

- Location: Gainesville, Florida

- Contact:

Re: Sand blasting experience

plastic media won't remove rust. you'll need something more abrasive (sand, soda, shell) or mechanical (sand paper, wire, etc).

Ben

Ben

Custom Sports Special

& High Performance Package

R E G I S T R Y

& High Performance Package

R E G I S T R Y

- reallylongnickname

- Sweptline.ORG Member

- Posts: 525

- Joined: Wed Dec 31, 1969 6:00 pm

- City: Ottawa, Ontario

- State: Foreign

- Location: Ottawa, Ontario

- Wildergarten

- Sweptline.ORG Pioneer

- Posts: 1768

- Joined: Wed Mar 21, 2018 5:27 pm

- City: Los Gatos

- State: CA

- Contact:

Re: Sand blasting experience

'69 W200 (thumbnail)

'68 W200 (RIP)

'68 W200 383 NP435 3.53

'67 W200 383 NP435 4.10 w overload springs, Dana 60, PTO winch & flatbed dump, racks, crane, c-air (Max)

Mark Vande Pol

Wildergarten.org

'68 W200 (RIP)

'68 W200 383 NP435 3.53

'67 W200 383 NP435 4.10 w overload springs, Dana 60, PTO winch & flatbed dump, racks, crane, c-air (Max)

Mark Vande Pol

Wildergarten.org

- reallylongnickname

- Sweptline.ORG Member

- Posts: 525

- Joined: Wed Dec 31, 1969 6:00 pm

- City: Ottawa, Ontario

- State: Foreign

- Location: Ottawa, Ontario

Re: Sand blasting experience

So what I understand for glass media is, 70 - 100 grit is most common. However, glass media grit can go 400 plus. I wonder which grit number stops being effective on metal? Curious on what the limit is. May not be pertinent information, more or less curious